3D vision technology is rapidly advancing, revolutionizing various industries with its ability to present stereoscopic images that were previously impossible with 2D vision. ToF 3D cameras and 3D sensing cameras are at the forefront of this field, offering accurate, detailed, and fast depth images that are ideal for applications such as Face ID, mobile phones, VR/AR, industrial vision, and more. In this article, we will explore the fascinating world of ToF 3D cameras and 3D sensing cameras, including their components, how they work, and the advantages of this exciting technology. We will also look at our companyVzense, a leading brand in the 3D sensing camera market, and the future of ToF 3D cameras and 3D sensing cameras.

Understanding ToF Technology and its Advantages

ToF 3D cameras and 3D sensing cameras are some of the most prominent technologies in this field. These devices use a variety of methods to obtain accurate, detailed, and fast depth images, making them ideal for applications such as Face ID, mobile phones, VR/AR, industrial vision, and more.

The Components of a ToF Camera and How They Work

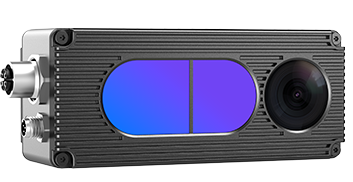

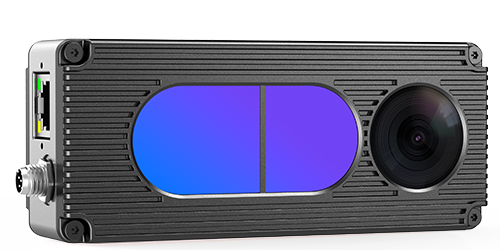

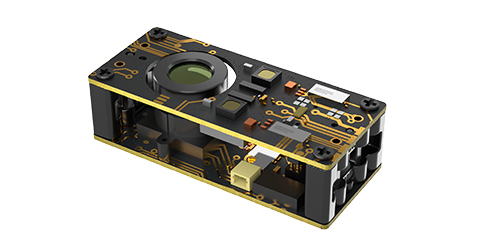

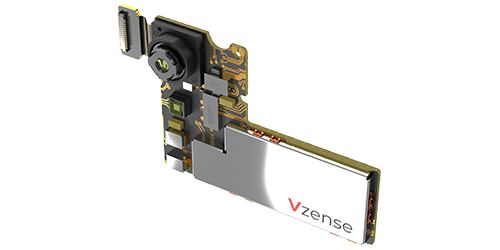

Our company,Vzense, a leading brand in the 3D sensing camera market, offers a range of cutting-edge products based on ToF technology. OurTheir advanced ToF cameras capture complete scene depth information in a single shot without the need for scanning devices. The ToF camera consists of several components, including the illumination unit, optical lens, imaging sensor, control unit, and calculation unit.

The illumination unit needs to pulse-modulate the light source before emission, and the frequency of the modulated light pulse can be as high as 100MHz. In the imaging process, the light source will turn on and off several thousand times, and each light pulse lasts only a few nanoseconds. The exposure time parameter of the camera determines the number of pulses per capture. To achieve accurate measurement, it is necessary to precisely control the light pulse to ensure that they have exactly the same duration, rise time, and fall time.

The optical lens is used to converge the reflected light rays onto the imaging sensor and is different from ordinary optical lenses in that it requires a bandpass filter to ensure that only light of the same wavelength as the illuminating light source can enter, thereby suppressing non-coherent light sources to reduce noise and preventing the photosensitive sensor from being overexposed due to external light interference.

The imaging sensor is the core of the ToF camera and includes two or more shutters for sampling reflected light rays at different times. The electronic control unit of the camera triggers the light pulse sequence in exact synchronization with the chip's electronic shutter opening/closing, reads and converts the sensor charge, and guides it to the analysis unit and data interface. Finally, the calculation unit records an accurate depth map, which is usually a grayscale image where each value represents the distance between the light-reflecting surface and the camera. Data calibration is also performed to achieve better results.

Vzense: Leading the Way in ToF 3D Camera Technology

In conclusion, 3D sensing cameras and ToF 3D cameras have come a long way since their inception and are now revolutionizing various industries. Vzense is at the forefront of this technology, offering cutting-edge products that provide unparalleled accuracy and speed. With advanced components such as the illumination unit, optical lens, imaging sensor, control unit, and calculation unit, ourtheirToF cameras can capture complete scene depth information in a single shot without the need for scanning devices.

Conclusion

As the technology continues to evolve, we can expect even more exciting applications for ToF 3D cameras and 3D sensing cameras in the future. With the ability to capture detailed and accurate depth images in real-time, these devices have the potential to transform numerous industries and enhance many aspects of our daily lives.

EN

EN

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)