If you want to improve the efficiency and accuracy of your manufacturing workflow, look no further than Vzense's 3D depth time of flight cameras. These cutting-edge devices offer a range of benefits for manufacturers, from enhanced quality control to streamlined production processes. In this blog post, we'll explore how Vzense's technology can help you take your manufacturing game to the next level. So buckle up and get ready to discover a world of possibilities!

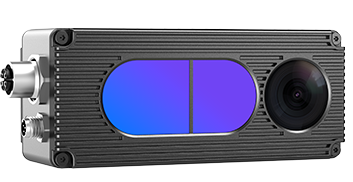

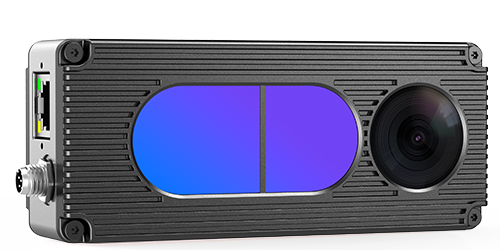

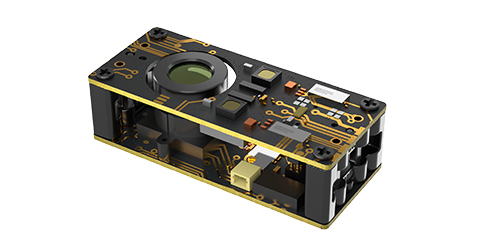

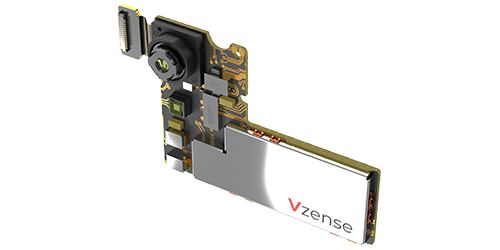

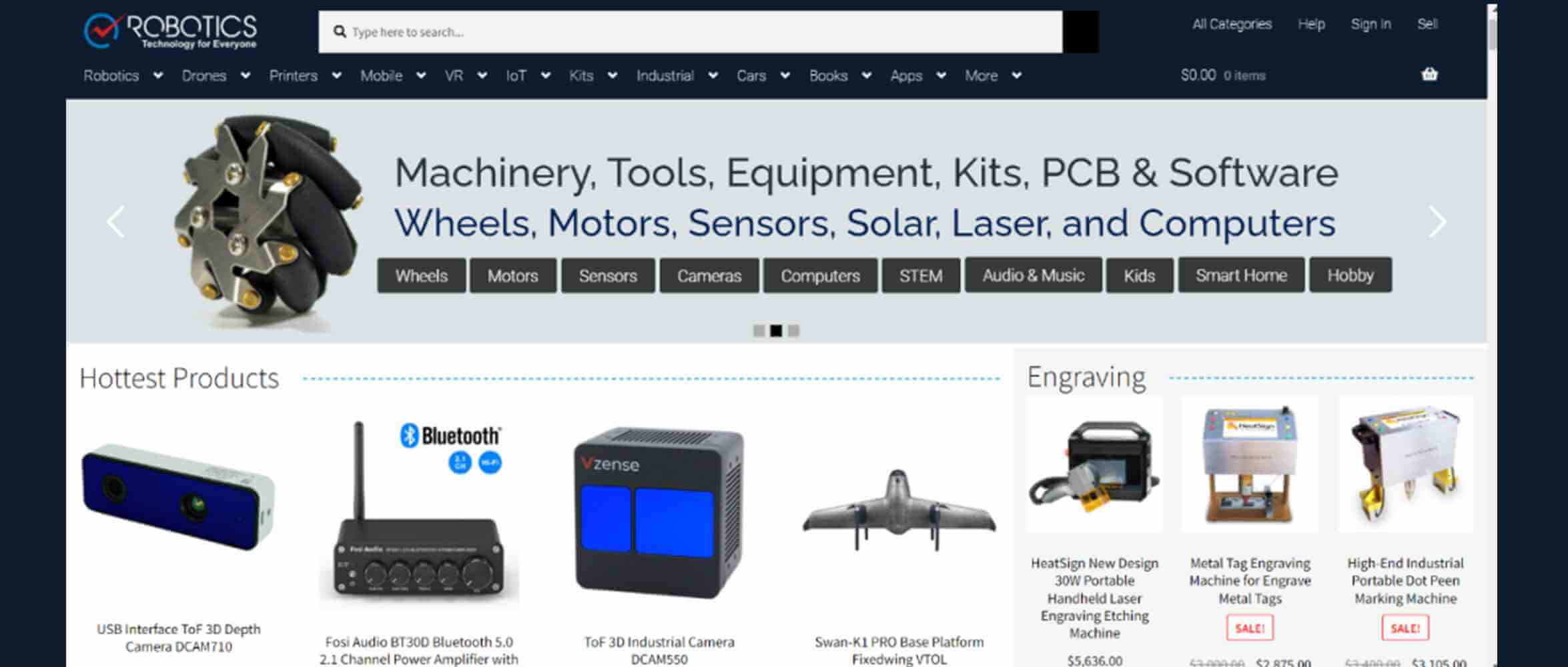

Introduction to Vzense's 3D Depth Time of Flight Cameras

Vzense's 3D Depth Time of Flight (ToF) cameras are designed to provide accurate and precise depth information for various manufacturing applications. ToF technology uses infrared light to measure the distance between objects, and Vzense's ToF cameras are equipped with an advanced algorithm that can accurately calculate depths up to 10 meters.

Benefits of Using 3D Depth Time of Flight Cameras in Manufacturing Workflows

Many benefits can be gained by using 3D Depth Time of Flight (ToF) cameras in manufacturing workflows. Perhaps the most significant benefit is accurately measuring distance and depth. This is especially useful in Quality Control (QC) applications, where ToF cameras can quickly and easily verify the dimensional tolerances of manufactured parts.

Another critical benefit of ToF technology is its high accuracy and repeatability. This makes it ideal for automated inspection systems, where consistent and reliable results are essential. Additionally, ToF cameras offer a wide field of view and are not affected by ambient light conditions, making them well-suited for use in various industrial environments.

Finally, ToF cameras are relatively low-cost and easy to implement, making them a viable solution for many manufacturing applications.

How Vzense's Technology Improves Efficiency and Accuracy

Vzense's 3D Depth Time of Flight cameras improve efficiency and accuracy in manufacturing workflows by providing a three-dimensional view of the production line. This allows for more accurate placement of objects and faster identification of potential problems. The technology also eliminates the need for costly and time-consuming laser scanning systems.

Best Practices for Implementing Vzense's Technology in Your Manufacturing

When implementing Vzense's 3D Depth Time of Flight technology in your manufacturing workflow, remember a few best practices. First, it is essential to clearly understand your manufacturing process and what specific tasks you want the 3D Depth Time of Flight camera to perform. This will ensure that you are using the camera in the most efficient way possible. Second, because the 3D Depth Time of Flight camera uses infrared light, it is essential to ensure there is no other source of infrared light in the area where the camera will be used. This can interfere with the camera's performance. Finally, because the 3D Depth Time of Flight camera is sensitive to light and dark objects, it is essential to calibrate the camera before use. This will ensure that the images captured by the camera are accurate.

EN

EN

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)