Vzense, a pioneering provider of innovative technology solutions, introduces its AGV pallet solution, powered by cutting-edge ToF (Time-of-Flight) technology. In this article, we explore the challenges faced by AGV forklifts in accurately identifying pallets in complex warehouse environments. Discover how Vzense's AGV Pallet Solution, with its advanced features and precise pallet identification capabilities, revolutionizes AGV efficiency and improves handling operations.

.jpg)

The Challenge of Pallet Identification in Complex Warehouse Environments

Warehouse operations often encounter challenges when it comes to accurately identifying pallets in complex environments. Warehouses feature various obstacles, racks, and structures that can create a complex and dynamic environment. AGV forklifts relying solely on mechanical position limitation or monocular cameras may struggle to accurately identify pallets amidst such complexity, leading to forklift deviations and reduced handling efficiency.

Manual handling and truck unloading can result in large deviations in the positioning and orientation of pallets. Traditional identification methods may not be able to handle such deviations, leading to inaccuracies in pallet detection and forking failure.

Revolutionizing Pallet Identification with Vzense's AGV Pallet Solution

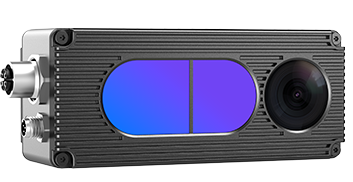

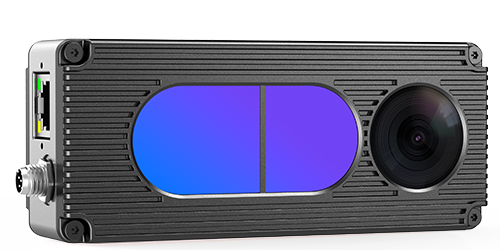

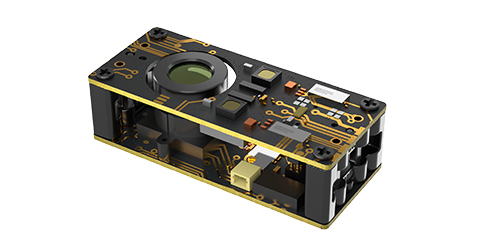

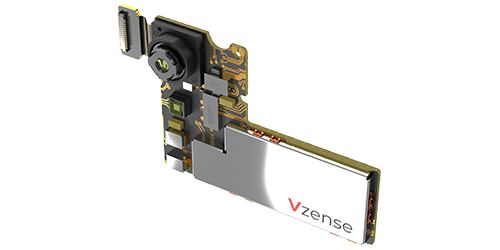

Vzense's AGV Pallet Solution addresses the challenges of pallet identification, leveraging the power of ToF technology. Vzense's AGV Pallet Solution employs ToF technology to achieve accurate and precise pallet identification. By capturing depth information, the solution can accurately detect and analyze the position, orientation, and dimensions of pallets in real-time, even in complex warehouse environments. This ensures optimal forklift alignment and reduces the risk of forking failure.

The AGV Pallet Solution utilizes advanced depth perception capabilities, allowing AGV forklifts to navigate and interact with pallets seamlessly. By accurately perceiving the depth of pallets, AGV forklifts equipped with Vzense's solution can adapt to deviations in positioning and orientation, improving handling efficiency and reducing the risk of damage to pallets or surrounding structures.

Vzense's AGV Pallet Solution significantly improves handling efficiency in warehouse operations. By enabling AGV forklifts to identify and align with pallets accurately, the solution minimizes forklift deviations and optimizes picking and placing operations. This leads to increased productivity, reduced downtime, and improved overall handling efficiency.

Conclusion

Vzense's AGV pallet solution, powered by ToF technology, revolutionizes pallet identification for AGV forklifts in complex warehouse environments. With its advanced depth perception capabilities and accurate pallet identification, Vzense's solution enhances AGV efficiency, reduces forklift deviations, and improves overall handling operations. Partner with Vzense to unlock the full potential of your AGV fleet, optimize handling efficiency, and drive operational excellence.

EN

EN

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)