Click on the link to watch the Youtube video.

Our Solution:

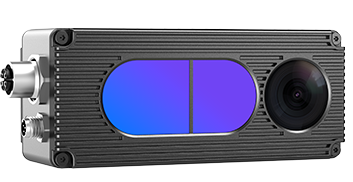

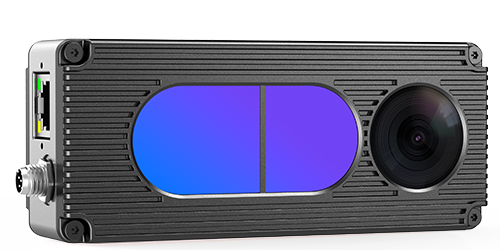

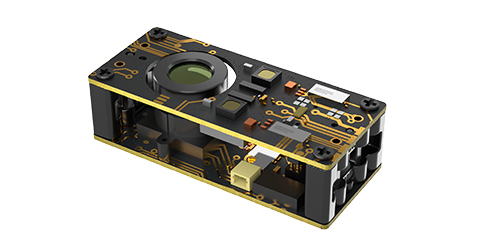

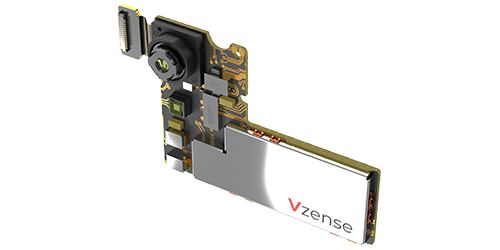

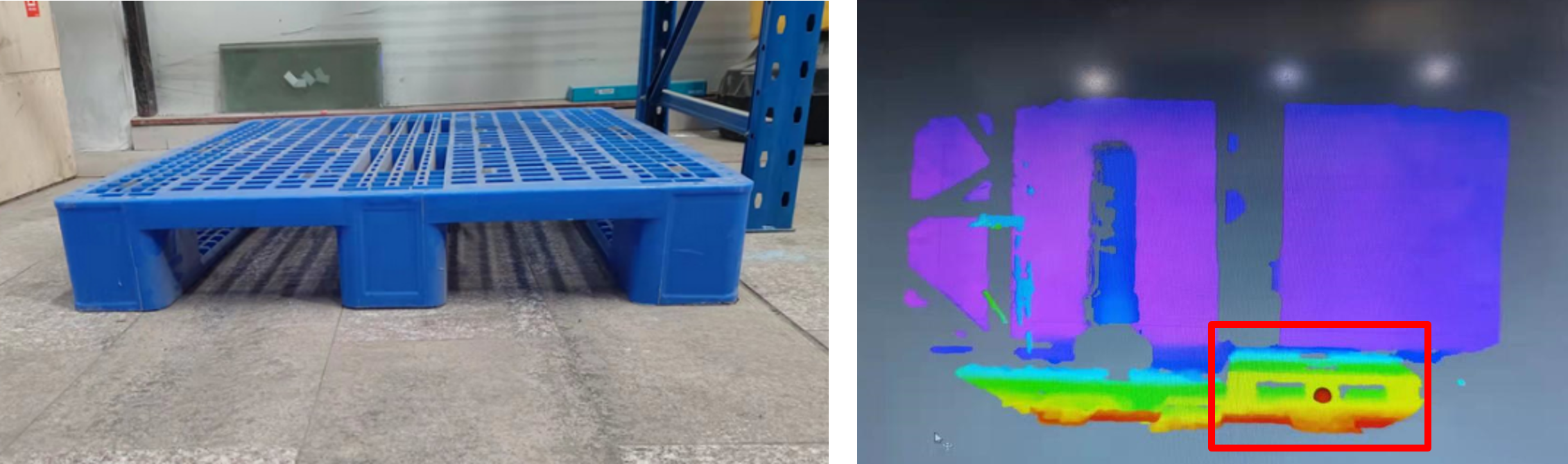

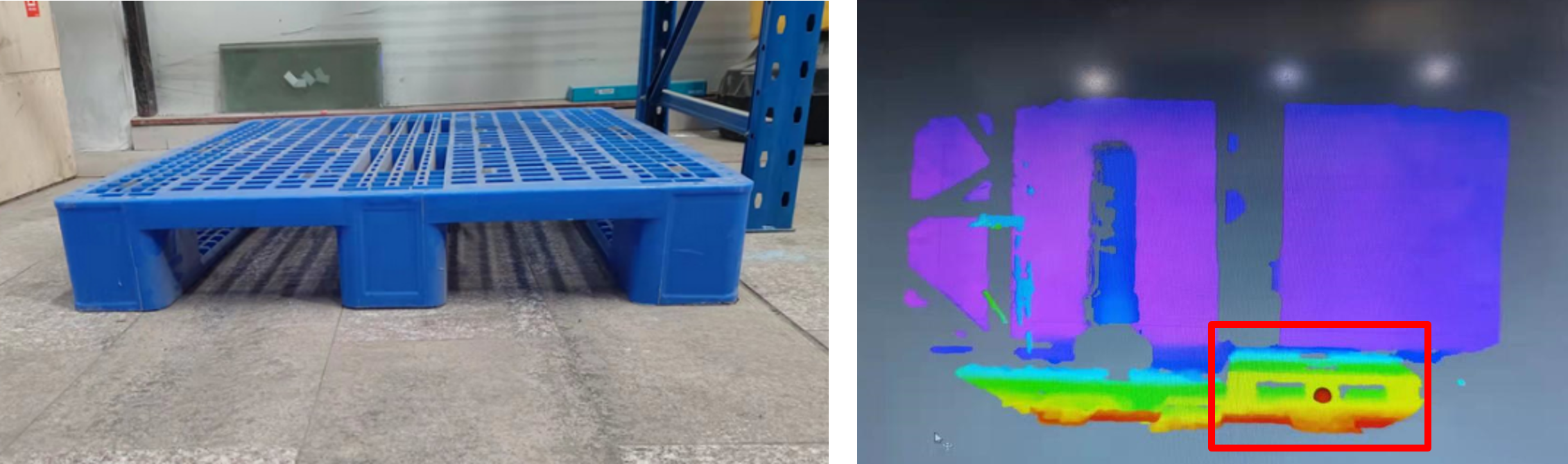

The industrial Vzense 3D ToF RGB-D Cameras capture pallet images and work with image processing algorithms to help the AGV forklift identify cargo, get their position and posture coordinates and adjust the fork direction intelligently. The unmanned intelligent handling of pallets eliminates overlarge deviation of the AGV forklift. In addition, by using our products, customers can develop and integrate Al algorithms more quickly, carry out intensive training and in-depth learning of the pallet recognition model, so as to improve the accuracy in handling the pallets.

Advantages:

- Based on the 3D ToF technology, not affected by ambient light (it works well in strong light or in the dark)

- Outputs 640x480 px VGA depth images

- Supports DC/PoE+ power supply, full SDK support

- Cost-effective price, spot delivery

- Multiple interfaces (USB, RJ45, aviation interface) and IP67 ingress protection

- Industrial-grade product with mature solution and stable performance, already mass-produced and used on many AGV models

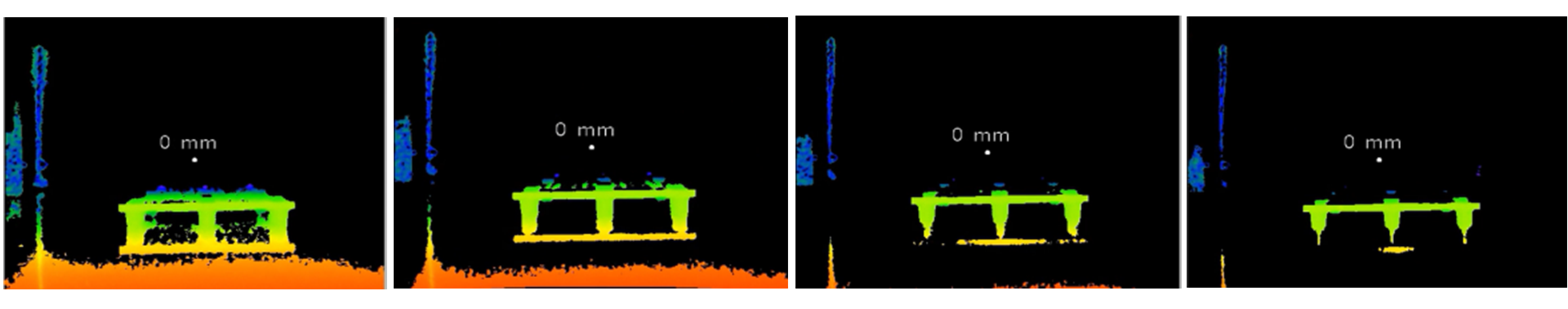

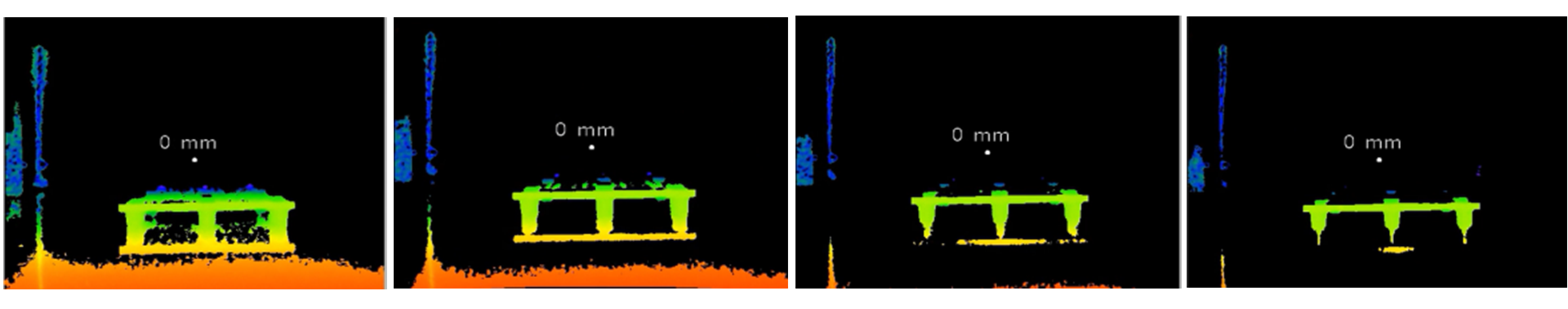

The following pictures show the depth image effect of the pallet 1.5m away at different confidence thresholds when the camera is working in Range 1 (0.5m~2.8m) mode.

Confidence threshold = 20 Confidence threshold = 25 Confidence threshold = 30 Confidence threshold = 35

EN

EN